MILK QUALITY AND ANIMAL WELFARE TRACKING MANAGEMENT

THE PROJECT

DEMETER is an H2020 project on large-scale deployment of farmer-driven, interoperable smart farming-IoT (Internet of Things) based platforms, delivered through a series of 20 pilots across 18 countries (15 EU countries). DEMETER’s objective is to empower farmers and farmer cooperatives to use their existing platforms and machinery to extract new knowledge to improve their decision making and to ease the acquisition, evolution and updating of their platforms, machinery and sensors by focusing their investments where these are needed.

CUSTOMER

Maccarese SpA farm, extending over an area of 3200 hectares, in a single body, is considered one of the largest agricultural companies in Italy, as well as one of the largest Italian entrepreneurial realities. It was born on March 20, 1925 as Maccarese SAB (anonymous company of reclamation) with headquarters in Milan and share capital of one million lire, with the aim of fully reclaiming an area of 4500 hectares belonging to the Rospigliosi. Due to the crisis of 1929, in the thirties it was sold to the I.R.I. At the moment, Maccarese farm hosts 1450 Friesian dairy cows, 600 fattening calves and 3.240 hectares of land.

THE NEED

The farmer already monitored his animals by using different smart devices, but collected data were scattered and prevented him from an overall vision of the most important animal welfare and milk yield indicators. Filling this lack of information has become increasingly urgent as a result of pressure brought by processing companies, willing to know data relating to the milk quality levels and by the consumers, claiming for more transparency regarding the food they eat.

The farmer needs to check several files, which separately allow the monitoring of different parameters related to animal welfare (such as rumination, eating habits, respiration, temperature, rest) and related to the milk (such as the relationship between fats and proteins which is related to ketosis and the values of electrical conductivity that are related to mastitis). It’s worth to say that milk quality is, indeed, closely linked to welfare of animals: an adequate eating and resting of animals will increase milk production and quality.

The farmer has to carefully monitor all the relevant parameters (both related to animal welfare and milk quality) captured in different files or provided by different systems in order to monitor his herd health and prevent or significantly reduce the use of antibiotics.

The processing company intends to know the milk quality levels since farmers are payed a variable premium based on pre-defined quality indicators of milk.

THE AIM

The project pilot aims to achieve two main results. First of all, the project aims to allow actors of the milk value chain to get an overview of animal welfare and insights on the quality of milk, that is strictly connected to the health of the animal. Secondly, the data collected need to be acquired by a traceability system that improves the communication between actors right up to the consumer, increasing food liability and trust.

THE APPROACH

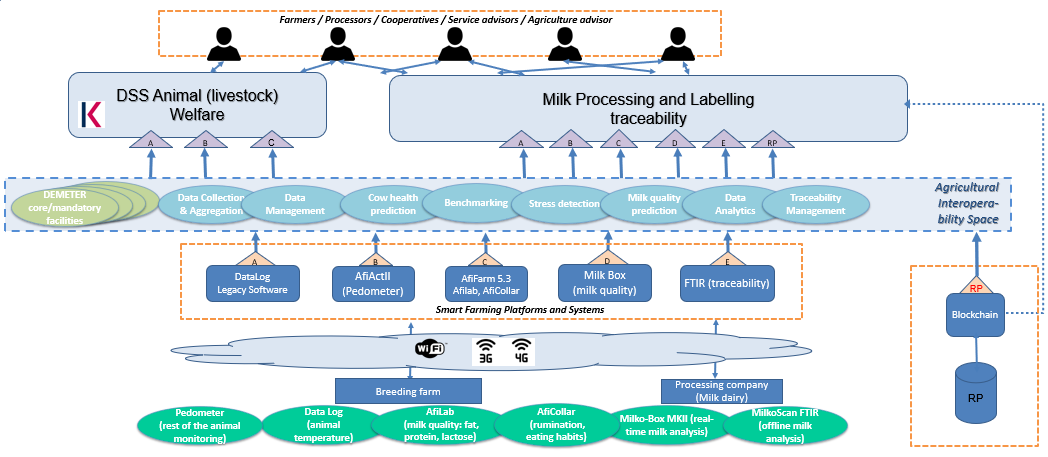

Two kinds of data sources are used: animal welfare-related data sources (collected through sensors which measure the animal rest, rumination, eating habits, etc.) and milk quality-related data source (samples analysis collected during collection and after processing, transportation and storage). Data are used by three systems:

- Estimate Animal Welfare Decision Support System (DSS): gives integrated insight on animal welfare and suggests corrective actions to the breeding farmer;

- Milk Quality Prediction: offers to the processing company a milk quality assessment taking into consideration the analysis of the raw milk coming from diary farms and the analysis of processed milk samples;

- Traceability System: provides consumer with the means to inspect, on a user-friendly dashboard, data gathered during all phases of the milk life cycle, in order to promote the awareness on the final product.

THE SOLUTION

New wearable devices for animals have been installed on site and their data have been integrated with data coming from already existing sensors on the pilot farm in order to optimize data quality & process. An Artificial Intelligence algorithm allows the evaluation of the health status of the cows, to determine the degree of well-being in terms of nutrition, hygiene, rest and movement, evaluating their productivity. All these data are visualized on the DSS dashboards, created through the DEMETER Adaptive Visualisation framework based on KNOWAGE technology.

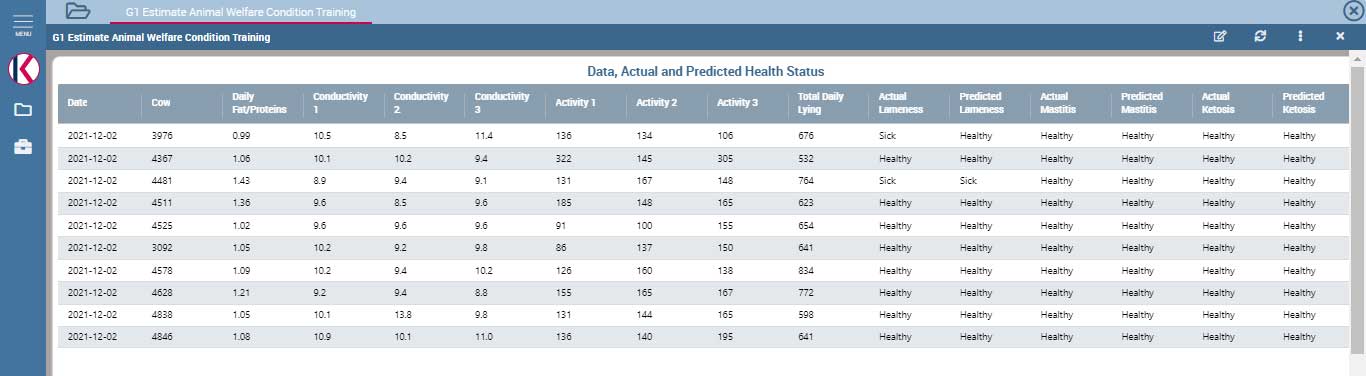

The Estimate Animal Welfare DSS dashboard allows to monitor the health status of the livestock and through the predictions allows to optimise the health of the herd. The table contains data about the fat/protein ratio, the electrical conductivity, their activity and the total daily rest, accompanied by two parameters: the health status by pathology assigned “manually” (Actual Column) and the health status by pathology assigned by the algorithm (Predicted Column). This is how the algorithm analyses the pathologies:

• Lameness (which analyses activity at rest): if the cow rests too little or too much, it may get too tired and limp or may already be lame and have difficulty getting up.

• Ketosis (which analyses the relationships between fats and proteins): if the diet is too unbalanced on fats, this can favor the onset of a ketosis status.

• Mastitis (which analyses the values of electrical conductivity): if the electrical conductivity of the milk exceeds a certain threshold, it is very likely that the cow is suffering from mastitis.

The dashboard also shows, for each pathology, two pie charts, to compare the health status “manually” assigned with those determined by the algorithm and a table showing the metrics. By observing the table and the forecasts made by the algorithm, it is possible to determine which parameters must be checked to improve the quality of the cow life. If the percentage of cows with mastitis exceeds a certain threshold, the hygiene procedures must be reviewed; if this happens for the ketosis ones, the feeding must be modified, making it more energetic and if the percentage of cows affected by lameness is too high, it is necessary review the housing spaces.

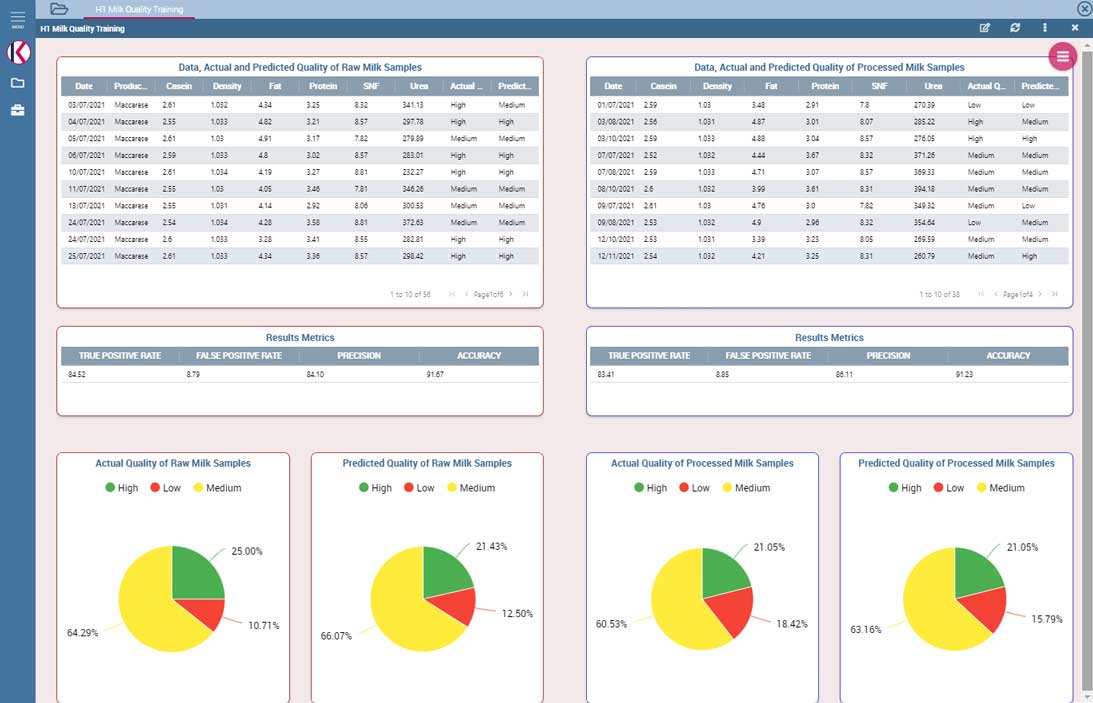

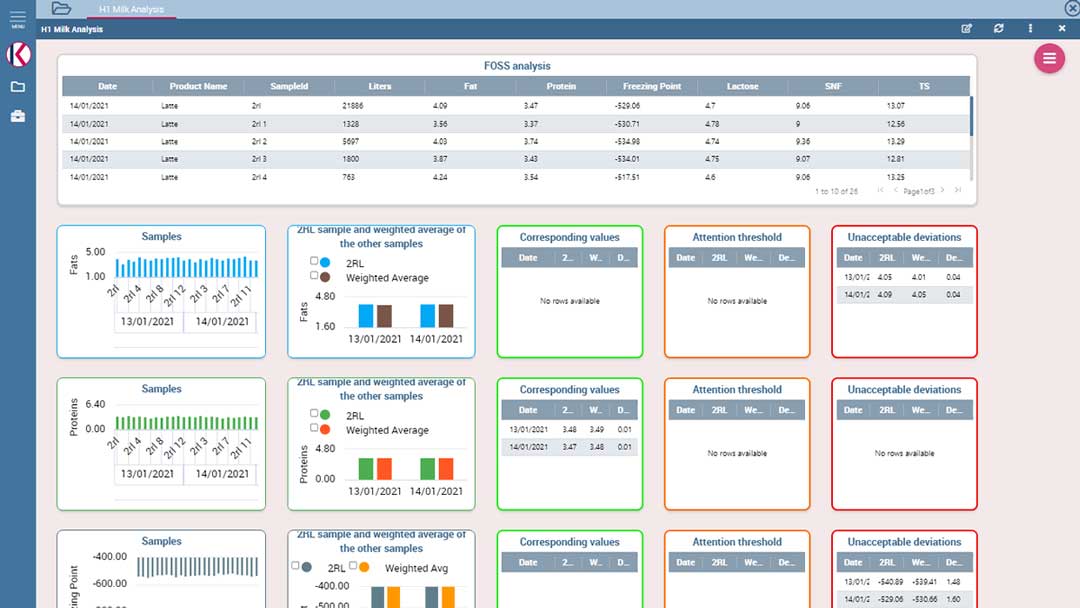

Milk Quality Prediction DSS dashboard monitors the milk quality level. This DSS enables processing company to establish the current level of milk quality for raw and processed milk through predictions of Machine Learning algorithms. These predictions enable the user to understand and optimize the quality of produced milk. The dashboard for raw milk shows a table with FTIR (Fourier-transform infrared spectroscopy) analysis accompanied by two parameters: the degree of quality “manually”assigned by the user for each sample and the degree of quality assigned by the algorithm, determined through the training performed on the values “manually” assigned. The dashboard also shows pie charts to compare the quality level “manually” assigned with the one determined by the algorithm, and a table showing the metrics that determine the accuracy of the algorithm.

THE RESULTS IN BRIEF

The solutions developed for our pilot in the DEMETER project have eased the extension of the information flow to new data sources, optimising the availability of scattered data in a single access point. This has resulted in a higher quality of milk and a fairer price for producers. It has lead to greater transparency on milk production and animal health for farmers and processors. For consumers, it can contribute to deliver improved transparency on product nutritional values, origins and animal welfare.

Matteo Boggian - Maccarese S.p.A.

“We already monitored our livestock through the analysis of different files and through our different systems collecting data related to animal welfare and milk characteristics. However we wanted to have an overall vision of the most important animal welfare and milk yield indicators through advanced visualisation techniques. The next step will be to integrate other animal welfare parameters, and that is what we are working on right now”